About Sophorolipids

About Sophorolipids

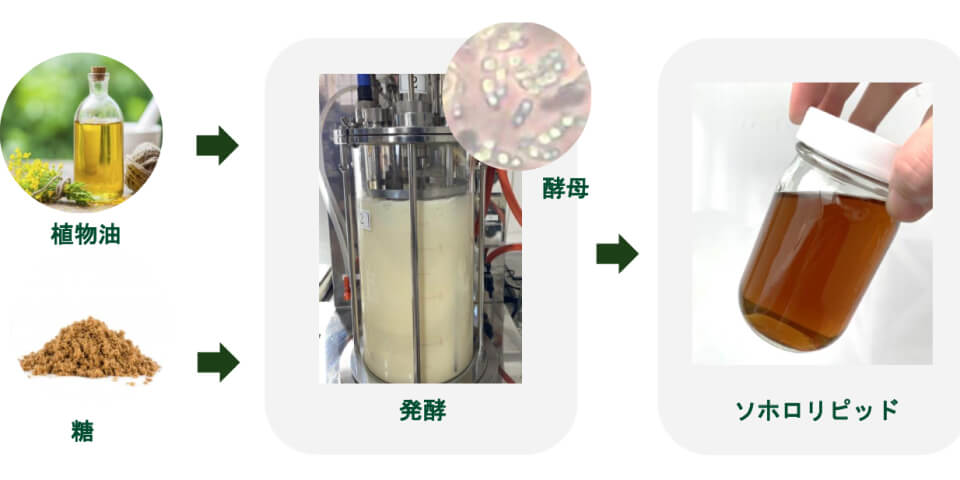

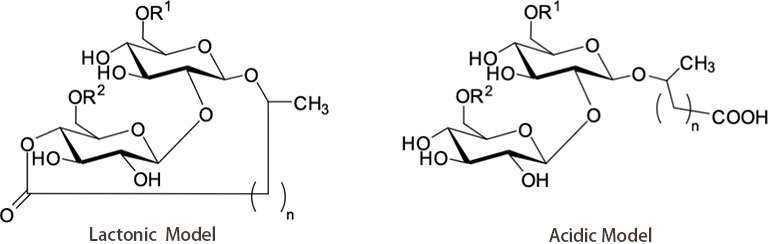

Sophorolipids are natural surfactant (surfactants produced by microorganisms such as yeast) made from vegetable oil, sugar, and Starmerella bombicola(non-pathogenic yeast). We use a structure that connects fatty acids and sophorose through an etherbond, and it is a mixture of the lactone form and It is economically challenging to make sophorolipids by chemical synthesis—this natural surfactant carries multiple possibilities for our future.

The Chemical Structure of Sophorolipids

Characteristics of Our Sophorolipids

1

Natural and GMO-free

Our sophorolipids use vegetable oil and sugar. Furthermore, we do not use GMOs at any point within the fermentation process. Finally, we do not make any chemical modifications—our product is created only through natural processes.

2

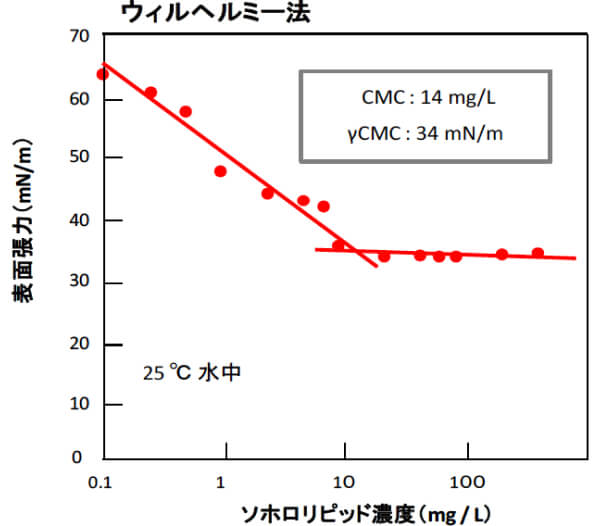

High Effect at lower concentration

Even in low concentrations, sophorolipids function as an excellent surfactant. This is 1/50-1/200 the concentration of sodium laurate (soap), and 1/20-1/5 the CMC (critical micelle concentration) of sodium dodecyl sulfate (SDS). It is thought to be due to the bulky molecular structure.

3

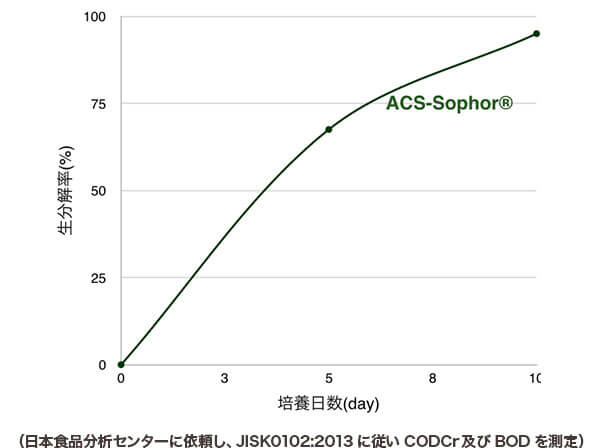

High Biodegradability

Sophorolipids boast high biodegradability, similar to soap. It is a more environmentally product compared to conventional synthetic surfactants. Due to the activity of microorganisms, sophorolipids are decomposed into water and carbon dioxide, and returned to nature.

4

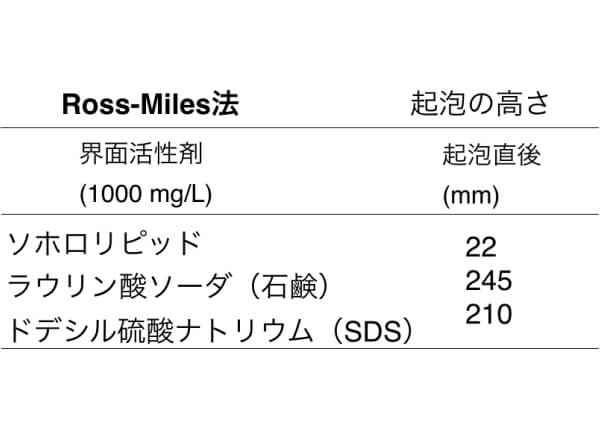

Low Foam Rate

Compared to soap and toothpaste, sophorolipids have 1/10 of the foaming rate. It is consequently easy to rinse and rarely stays on skin and clothes. Sophorolipids are thus characterized by low skin irritation.

5

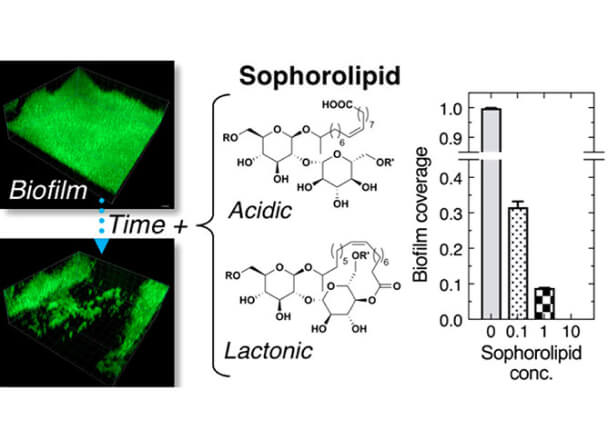

Inhibition of Biofilm Formation

Sophorolipids remove biofilms (microbial communities) formed by bacteria without killing them. Because the biofilm is peeled off while weakening its cohesiveness, it becomes possible to suppress the emergence of resistant bacteria.

Nguyen, B.V.G., T. Nagakubo, M. Toyofuku, N. Nomura, A.S. Utada,

Synergy

between Sophorolipid Biosurfactant and SDS increases efficiency of

P. aeruginosa biofilm,

disruption. Langmuir, 2020 Apr,

doi: 10.1021/acs.langmuir.0c00643

Applied Uses of Our Sophorolipids

Environmentally friendly biosurfactants that put people first

Sophorolipids have low impact on the environment and on our bodies. Its capacity to be highly effective even in small amounts makes it possible to develop a wide range of applications. Currently, we are focused on livestock additives (co-developed with Rock Chemical Products) and personal care products (co-developed with BASF). Medium-to-long-term application development research is also underway with various partners.

Livestock Business

Livestock feed additive stabilizer

- ・Emulsifier

Personal Care Business

Cleaning Agents

- ・Detergent

- ・Shampoo

- ・Mouthwash

- ・Toothpaste

-

High strength detergent

-

Biofilm removal/suppressant effects

(smell, dandruff, bacteria suppression)

Personal Care Products

Cosmetics

- ・Emulsifier

- ・Moisturizer

- ・Penetration Enhancer

-

Good for sensitive skin

-

Biofilm removal/suppressant

(maintains cleanliness of skin)

Other

Laundry Detergent

- ・Household laundry detergent

-

High strength detergent

-

Low foaming rate (easy to rinse, minimal residue on clothing

-

Low chemical impact (longer-lasting clothes)

Other Business

Industrial Use

- ・RO filters treatmennt

-

Biofilm removal/suppressant effect

-

Low chemical impact

(long-lasting filters)